ADVANCED OPTICAL MODULATION TECHNOLOGY

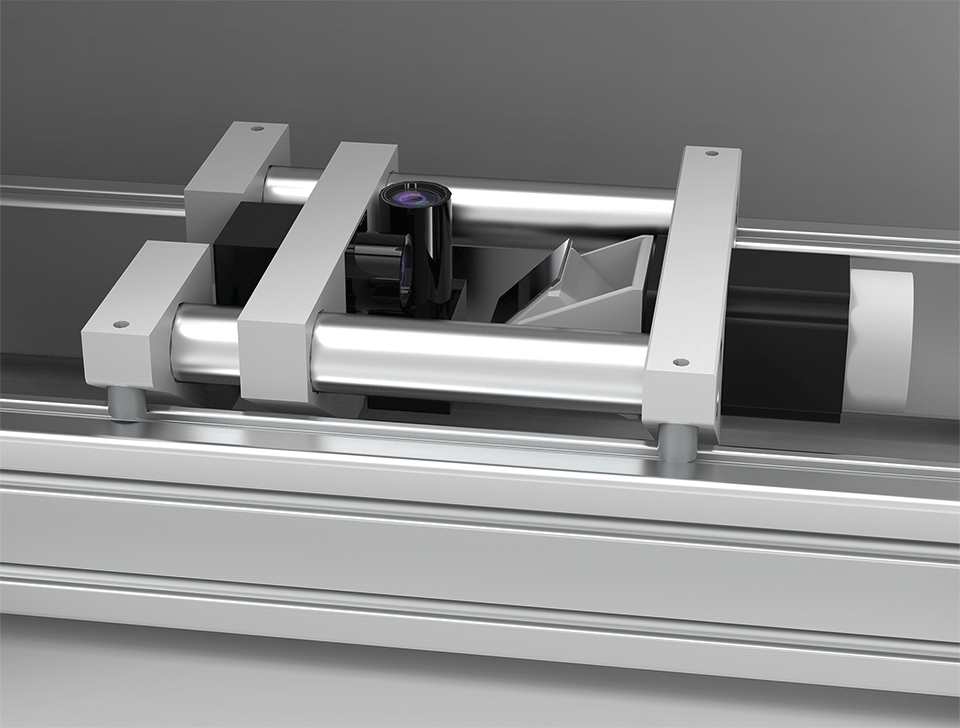

ADOMO® technology is at the heart of the MODI systems. It consists of a high-resolution Camera. With a diverting motorized mirror, the camera captures the object immediately and directly. The rapid movement of the mirror happens both on the horizontal and on the vertical axis. The camera's field of view can be very quickly and precisely in all directions be changed.

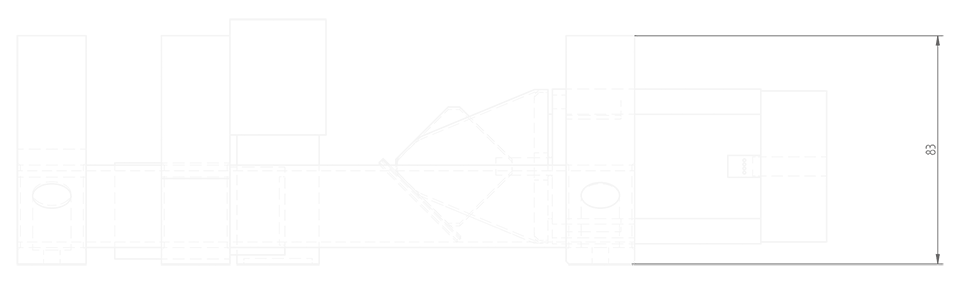

The patented ADOMO® technology offers the industry a seamless and detailed recognition of codes and labels. In addition to the high-resolution detail camera the other overview camera is used for this purpose, the exact position of all labels that in the 380 x 380 mm reading area are to be determined. The coordinates are immediately to the mirror movement control sent and the deflecting mirrors align Accordingly, the detail camera the label quickly and precisely. In this way, the Camera resolution completely only on the label to be read. The entire hardware performance is efficiently only to this area. This leads to the shortest cycle times and the highest Reading accuracy.

With the maintenance-free high-speed Mirror deflection system from MODI mirror positions within 20 ms can be changed. This guarantees a high working speed and shorter cycle times. In contrast to this is the idea of other providers that the camera itself to the corresponding object using of a deflection unit. However, this technology requires a more vulnerable construct. This inevitably leads to a high wear of the individual parts with a slower alignment speed. ADOMO® technology has been the fastest and most precise system on the the relabeling market.