Link between code scanner and traceability system

Optimizations in label recognition through to the improved user interface

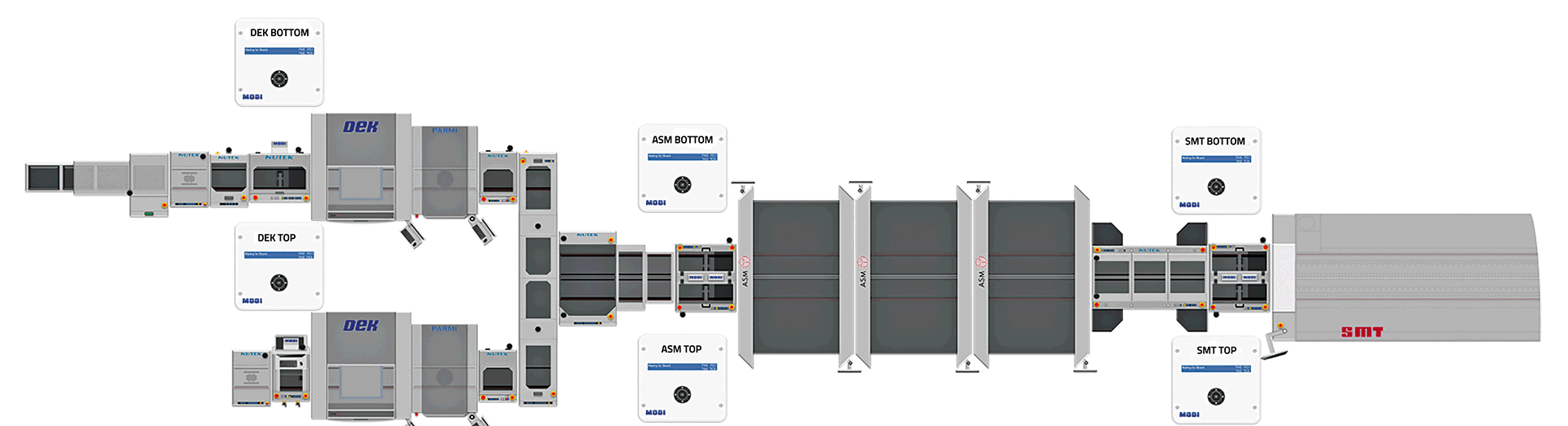

The MODI IBox is the link between

a simple code scanner and the

Traceability System.

Make any conveyor belt

into an intelligent process system.

With the integrated SMEMA interfaces

the IBox is placed between two machines

integrated.

It is not necessary to adapt the respective system control.

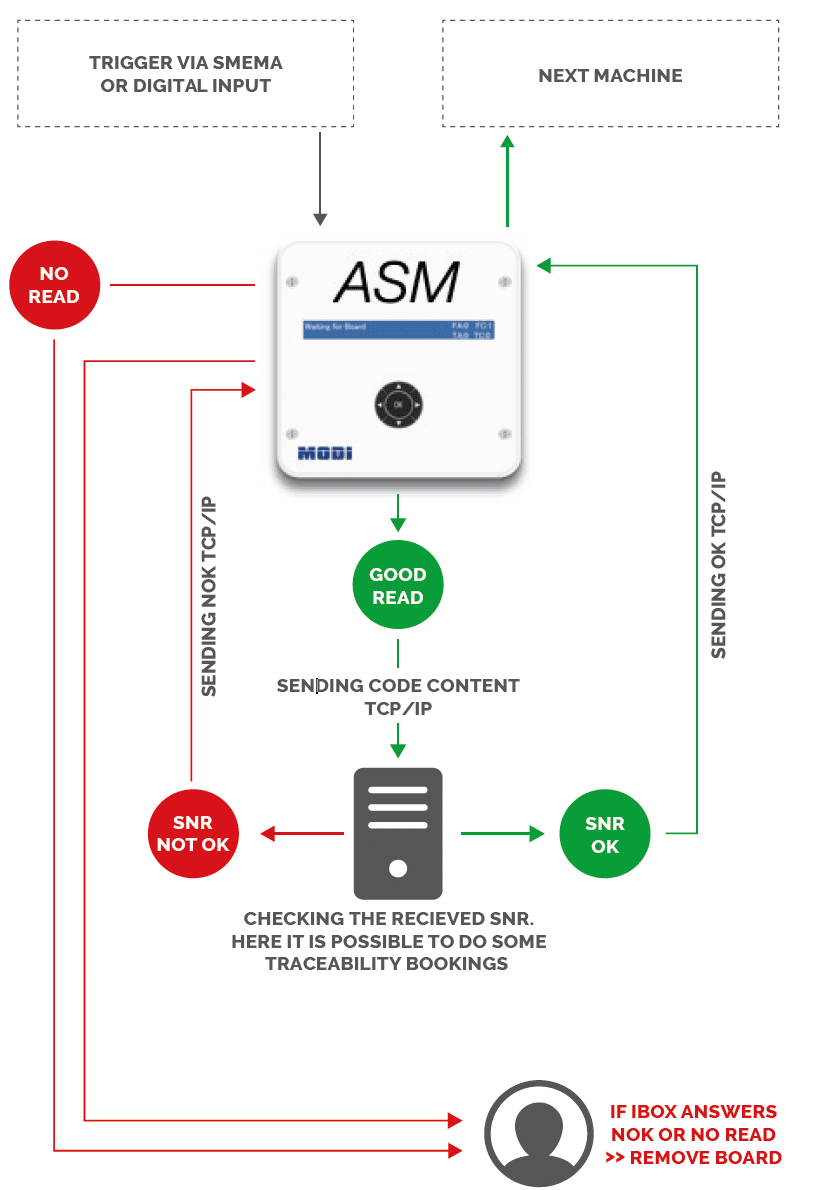

The board transfer serves as a trigger for

the code reading process. Any

Scanner can be easily connected via RS232.

The read code contents are saved via

TCP/IP to the traceability.

This is where the check takes place:

If the current board is allowed to

process step?

If approval is granted by the

Traceability System, the SMEMA interfaces will be

opened by the IBox and

the board can be installed in the following machine

retract. In the event of negative feedback

a corresponding error message

shown directly on the IBox display

become.

The IBox server software is installed on the line master computer and can handle any number of Control IBoxes. These are connected to the software via a network. A graphical user interface allows the operator to monitor all processes at any time. monitor. Individual scripts allow each device to run through a process-specific workflow.

The IBox can read the code contents directly to downstream machines pass on. An installation of a code scanner into the respective process system is therefore not absolutely necessary. The Connection can be made via RS232 or network can be realized.

Every production has its own special features. Every traceability system has specific interfaces. Advice in individual workshops you to optimally integrate the IBox into your existing processes. Talk to us and make an appointment You make an appointment.