INCOMING GOODS SYSTEM 5.0 - New version, more efficiency

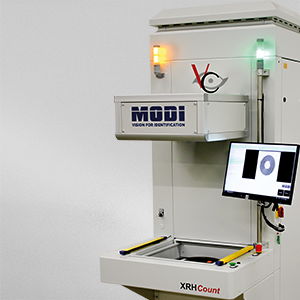

The MODI incoming goods system WES V5 combines intelligent information processing from captured images and data administration into a fundamental building block of Industry 5.0. Goods receipt is the most popular scenario for the MODI system.

In modern industry, components must be must be traceable throughout the entire production process. This ensures that you can ascertain which product contains which batch/lot number/date codes of components, and when and where they were integrated. During the initial reading process, manufacturer product information is read and compared with a customer‘s article master database or the ERP system. Only when data identity is confirmed, the system grants clearance for the item.

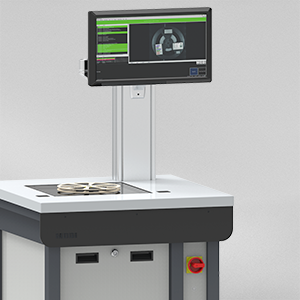

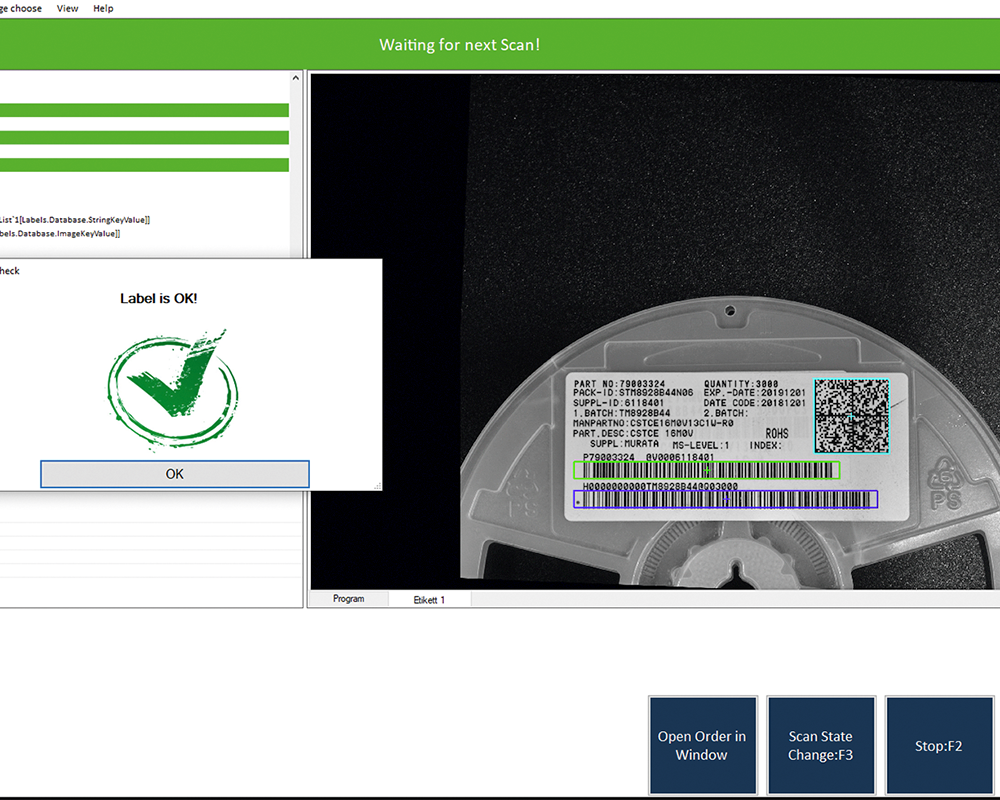

The system relieves operators of any inspection activities and shines through process reliability. With continuous height adjustment, the system can be tailored to fit any operator. Reading and comparing label information in 1 - 2 seconds. Hardware and software development under one roof. We are able to react flexibly to customer requirements and coordinate solutions.

The process starts with the recording of incoming goods before they are posted in the ERP software. For a delivery, there is a delivery note and/or ASN (Advanced Shipping Notification) information available. These constitute the expected material scope. Optionally, the delivery note can be archived as a PDF. The required document scanner can be directly accessed from the MODI software for this purpose.

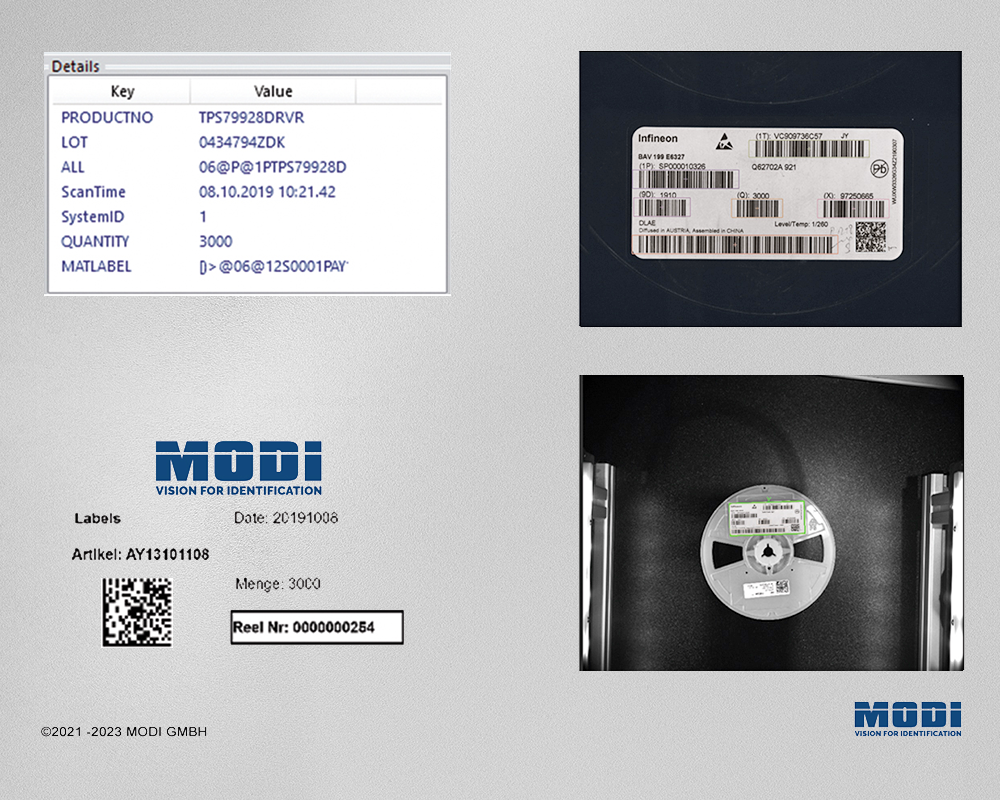

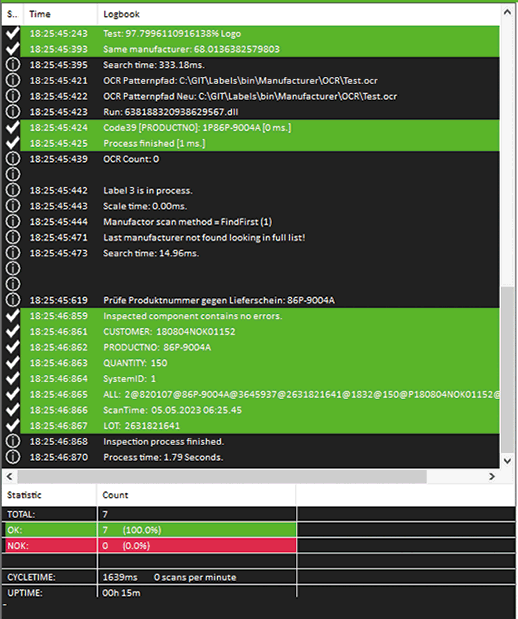

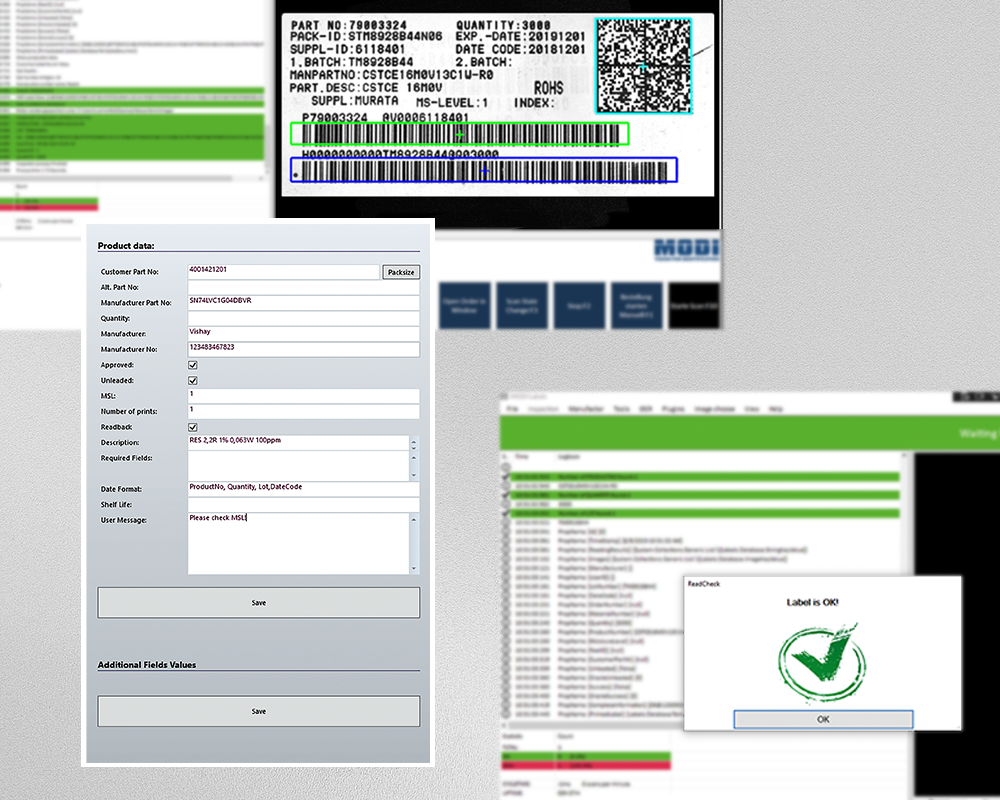

Now the operator begins processing the delivered items in any order. For example, when a component roll is placed on the reading surface, the manufacturer‘s label is read and registered within seconds. All captured content is immediately compared with the article master database. If all information matches and the item is approved, a customer-specific label with a unique identification number is generated. The label is placed on the component roll and verified in a verification process. This confirms whether it contains the correct content on the correct material. After this step, the process is completed for the operator.

Once the expected quantity from the ASN and delivery note is reached, the booking is triggered in the ERP software. In the background, all mechanisms that ensure traceability are running. Comprehensive information is stored in the traceability database. All read information, as well as image documents, booking and clearance information, are uniquely associated with a customer label. MODI feeds your assembly and storage systems with all necessary data to optimize all subsequent processes here as well. The generated unique ID guarantees traceability throughout the entire process chain.

System improvements should always be a significant part of hardware and software. New features like AI roll measurement or optimized document evaluations are part of these enhancements!

Complete delivery notes can now be captured using text recognition. Targeted learning and automatic data capture are now possible. Scanned product numbers can be directly matched with the delivery note. However, MODI still recommends comparing them with the order data from your ERP system.

The diameter of rolls is determined during the scanning process. This enables optimized storage. Prevent the storage of rolls that your assembler cannot process. All of this is done right at the incoming goods area!

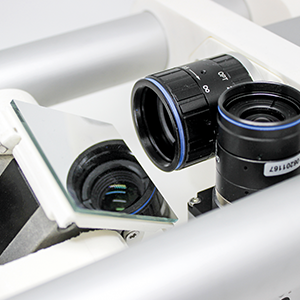

The improved camera technology in WES V5 captures all labels at once. High-resolution images ensure 100% traceability. Reading quality and processing times are significantly optimized, making work easier!

Improved user interfaces make working with MODI WES even easier. The clean interface displays key data at a glance. The newly implemented Dark Mode is easy on the eyes.

LED CLASSES 100% TRACEABILITY

etc.

MODI, with its extensive experience, offers a diverse range of standardized incoming goods processes and interfaces for ERP, EMS, LVS, or placement machines. However, as seen with deployed ERP solutions, many processes in customer use are individually structured. Therefore, complex processes often require a joint workshop is recommended in advance in order to develop a customized define the workflow in detail. This process can then be adapted 1:1 from MODI implemented in software and integrated into the existing LABELS operating software become. This means that every customer can find the perfect process ideas again and the entire Goods receipt recording can be efficiently and error-free in just one workplace.

Once a label is captured by the camera, it undergoes a filtering process. This process identifies around 80% of label structures. Automatic recognition is achieved through identifiers that precede the actual barcode content, uniquely identifying it. If these identifiers are absent, there‘s the option to train the system with manufacturer labels. This is a one-time process per manufacturer label type. For individual barcodes, freely definable information fields can be assigned. Furthermore, composite code contents in string format can be broken down into individual pieces of information. This way, all contents can be reliably assigned and recognized, even without identifiers.

Through automatic quality recognition, well-printed content is read without manual inspection and passed on to subsequent systems. In cases of poorly printed information, the operator is given the option to verify, modify, or confirm that information. A classic example is labels with essential identification information printed in human-readable text without a barcode. Often, manual input by an employee is needed for registration and processing of incoming goods. With the MODI OCR solution, human-readable text information is automatically processed, read, and transferred to subsequent systems and the traceability database. Labels that used to require significant effort in terms of additional handling and security are now easily managed.

MODI GmbH strives to manufacture a customized product for its customers. Accordingly, we also see ourselves in the position of a consultant so that production processes can be optimized. The necessary processes are integrated directly into the individual workflows through subsequent workshops at the customer’s premises. MODI therefore offers customized solutions in all areas.

The MODI software can be easily integrated into existing systems. There are various scenarios that can be realized:

In addition to the standard ERP connection, the MODI system is also able to communicate with various MES, warehouse management and placement systems, so that optimum and customized integration into the processes can be guaranteed.

An ergonomic workstation is all about ensuring that work is carried out efficiently and without errors. The MODI system can be adapted to any operator thanks to its infinitely variable height adjustment. Staff therefore work more efficiently and with fewer pain-related breaks due to tension in the neck area. Even if the same activity is carried out over a longer period of time, employees are protected from damage to their health and later also from absences due to back problems.