Specialist for identification solutions & process optimization

MODI Modular Digits GmbH has been a specialist in identification solutions and process optimization in the area of goods receipt and production for the electronics and pharmaceutical industries for more than 30 years.

MODI is the right partner when it comes to solution concepts for incoming goods through to production. As an expert in image processing, MODI has developed many products over the years to optimize these processes with innovative and highly efficient technology.

All hardware and software development takes place in-house, which guarantees a high degree of flexibility and dynamism with regard to further developments and customer requirements.

At our Technology Center, we offer a wide range of training courses, workshops and discussions aimed at deepening specialist knowledge, exploring current trends and jointly developing solutions for the challenges of today and tomorrow.

Valuable business relationships have been established through international projects and a wide range of customer requirements. Constantly changing customer requirements have led us to design all our products modularly and individually.

Tailor-made inspection solutions and customer-specific booking processes for incoming goods and traceability make our products universal and suitable for use in a wide range of industries.

The combination of the

COMPLETE TRACEABILITY FOR CUSTOMER AND QUALITY AUDITS!

In modern industry, it must be possible to track components throughout the entire production process. This ensures that you can ascertain which product contains which batch/lot number/date codes of components, and when and where they were integrated.

Learn more

Link between code scanner and traceability system

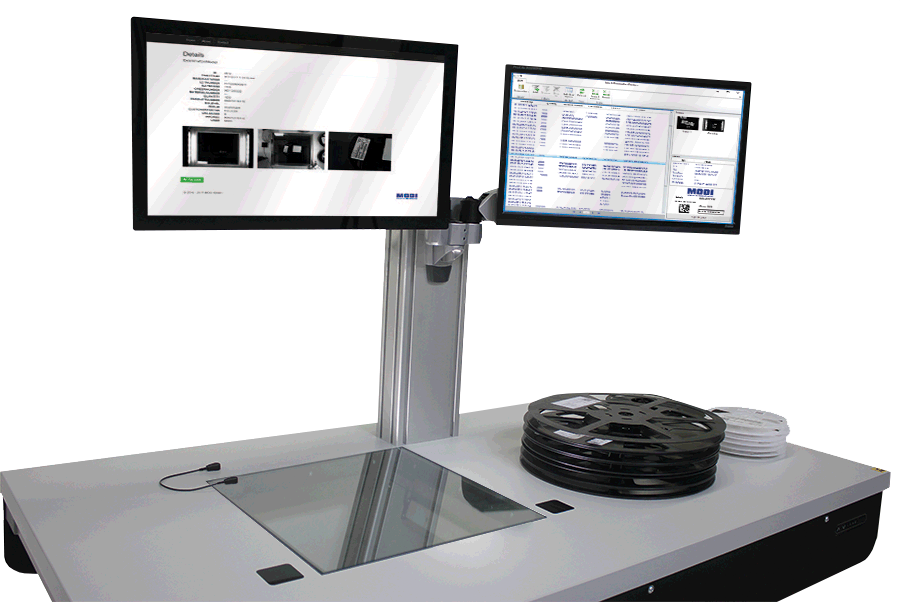

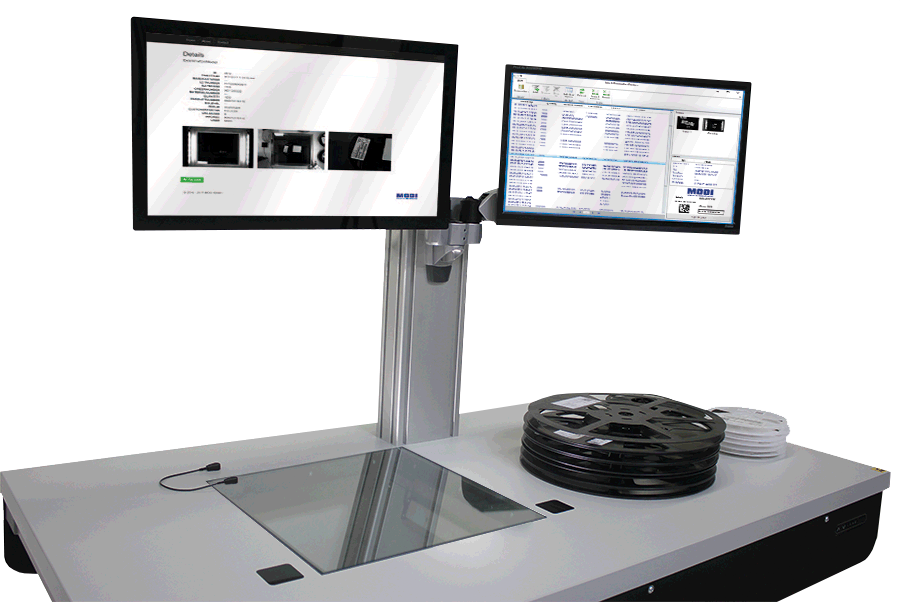

The MODI IBox is the link between a simple code scanner and the traceability system.

Learn more

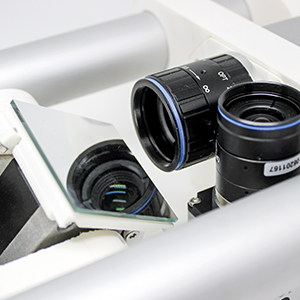

ADOMO® technology is at the heart of the incoming goods scanners. It consists of a high-resolution camera with a zoom lens. With a deflecting motorized mirror, the camera captures the object to be detected immediately and directly.

Learn more

The balancing unit is used to balance products during production and to record samples when carrying out a media fill. All counting processes are documented (digitally and in paper form).

Learn more

COMPLETE TRACEABILITY FOR CUSTOMER AND QUALITY AUDITS!

In modern industry, it must be possible to track components throughout the entire production process. This ensures that you can ascertain which product contains which batch/lot number/date codes of components, and when and where they were integrated.

Learn more

Link between code scanner and traceability system

The MODI IBox is the link between a simple code scanner and the traceability system.

Learn more

ADOMO® technology is at the heart of the incoming goods scanners. It consists of a high-resolution camera with a zoom lens. With a deflecting motorized mirror, the camera captures the object to be detected immediately and directly.

Learn more

The balancing unit is used to balance products during production and to record samples when carrying out a media fill. All counting processes are documented (digitally and in paper form).

Learn more

The doors to our new Technology Center will open on April 1, 2024. At our Technology Center, we offer a wide range of training courses, workshops and discussions aimed at deepening specialist knowledge, exploring current trends and jointly developing solutions for the challenges of today and tomorrow.