INCOMING GOODS SCANNER 5.0 - THE TRANSPARENT INCOMING GOODS SCANNER

Wherever visual checks and manual input by an operator are required for incoming goods registration, the risk of incorrect stocking increases.

In modern industry, component tracking is crucial. Our system captures and saves information from labels on goods, including barcodes and data matrix codes, in order to pass them on in the production processes.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam.

The process begins with the recording of incoming goods before they are posted in the ERP software. Delivery bill and/or ASN (advanced shipping notification) information is available for a delivery. These form the expected material scope. All information is available using an order or material document number.

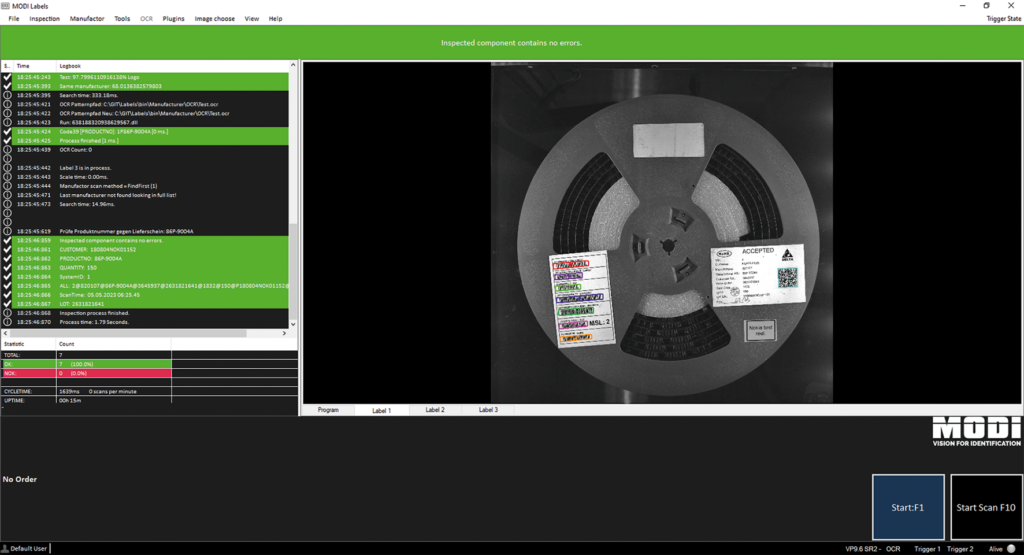

The operator now begins to process the delivered items in any order. If, for example, a component roll is placed on the reading surface, the manufacturer label is read within a second and compared with an article master database. If all the information matches and the item is approved, a customer-specific label with a unique ID is issued. This is placed on the component roll and checked in a counter-reading process. This checks whether the label with the correct content is on the correct material. The process is now complete for the operator.

Once the expected quantity from the order has been reached, the booking is triggered in the ERP software. All the mechanisms that ensure traceability run in the background. Extensive information is stored in the traceability database. All read information as well as image documents, booking and release information are clearly assigned to a customer label here.

The Labels software can be connected to a wide range of ERP, trace and warehouse systems. Thanks to customer-specific processes, the incoming goods scanner can be deeply integrated into the workflows and therefore offers the best combination of efficiency and security. The diagram shows the system processes and the multiple checks of the delivered components.

Once a label has been captured by the camera, it goes through a filter process. Approx. 80% of all label structures are recognized here. This automatic recognition takes place via identifiers that are placed in front of the actual barcode content and uniquely identify it. If these are not available, it is possible to train the manufacturer labels. This is done once for each manufacturer label type. Freely defined information fields can be assigned to individual barcodes here. Furthermore, composite code content in string format can also be broken down into its individual pieces of information. In this way, all content can be reliably assigned and recognized even without an identifier.

New functions make it possible to read non-coded information reliably and without errors. This means that in future >will be able to capture 99% of the labels on the market. Automatic quality recognition means that well-printed content is read without manual checking and forwarded to downstream systems.

MODI strives to provide its customers with a product that is individually tailored to their needs. Accordingly, we also see ourselves in the position of a consultant so that production processes can be optimized. The necessary processes are integrated directly into the individual workflows through subsequent workshops at the customer’s premises. MODI therefore offers customized solutions in all areas.

The MODI software can be easily integrated into existing systems, so there are various scenarios that can be realized:

In addition to the standard ERP connection, the MODI system is also able to communicate with various MES, warehouse management and placement systems, so that optimum and customized integration into the processes can be guaranteed.

An ergonomic workstation is all about ensuring that work is carried out efficiently and without errors. The MODI system can be adapted to any operator thanks to its infinitely variable height adjustment. Staff therefore work more efficiently and with fewer pain-related breaks due to tension in the neck area. Even if the same activity is carried out over a longer period of time, employees are protected from damage to their health and later also from absences due to back problems.